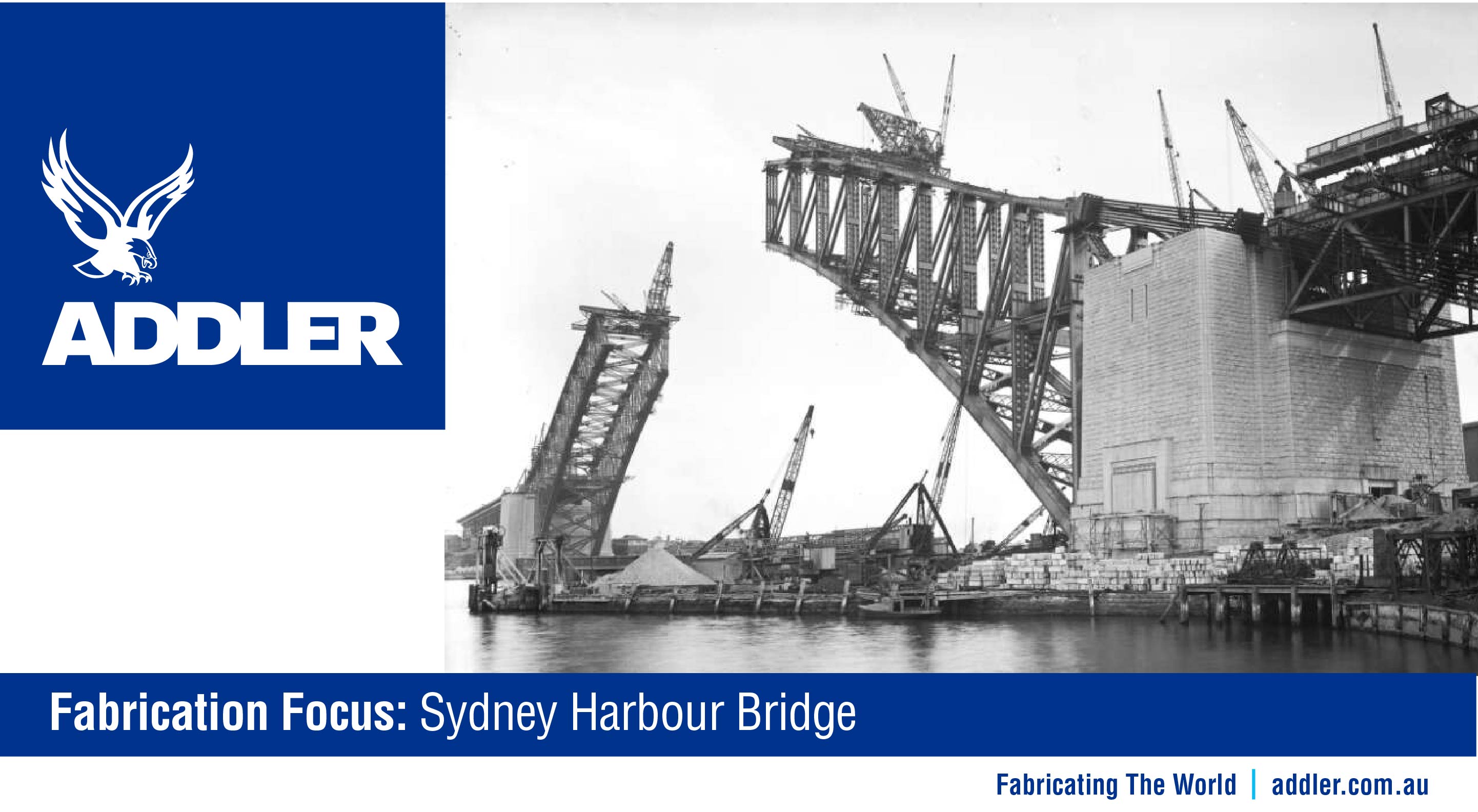

The Sydney Harbour Bridge is a renowned international symbol of Australia, an icon of Sydney, and holds the record of being one of the world’s largest steel bridges.

The Sydney Harbour Bridge construction started in 1926 and was opened on 19th March 1932. It took 1,400 men to build the bridge at a cost of $4.2 million, and the lives of 16 persons.

As Chief Engineer of Sydney Harbour Bridge and Metropolitan Railway Construction from 1912, Dr Bradfield is regarded as the “father” of the Bridge as it was his vision, enthusiasm, engineering expertise and detailed supervision of all aspects of its construction, which brought Sydney’s long held dream into reality.

10 Interesting Facts you probably didn’t know about The Sydney Harbour Bridge:

- The bridge contains 53,000 tonnes of steel.

- 589 tonnes of steelwork was erected on the arch in one day on 26 November 1929.

- The bridge gained the nickname the Iron Lung for providing work for many persons during the great depression.

- Captain Francis De Groot of the para-military group, the New Guard, slashed the ribbon prematurely with his sword, prior to the official cutting which was meant to be carried out by the NSW Premier, the Hon. John T. Lang.

- There are about 6 million Australian made rivets used in the bridge, and the largest of these would be the 395mm long rivets which weighed around 3.5 kilograms.

- The 89m high pylons of the bridge used around 17,000 cubic meters of granite blocks quarried near Moruya and transported 300km north to Sydney.

- It took 272,000 litres of paint for the initial 3 coats of the harbour bridge (The surface area that requires painting is equal to about the surface area of 60 sports fields).

- Due to the hot Sydney sun, the Bridge has huge hinges to absorb the expansion of 420mm for the deck and 180mm for the arch.

- Homes of up to 800 families living along the path of the bridge were also demolished without any compensation given.

- In June 1976, the one-billionth vehicle crossed the Sydney Harbour Bridge (The first 500 million crossings took over 33 years while the second 500 million took less than 11 years!)

ADDLER is focused on Helping Metal Fabricators Succeed in Australasia. We aim to provide the most efficient metalworking products and solutions to ensure manufacturing and construction in Australia continues. We help you fabricate the world.

Visit www.addler.com.au or call 1300 90 50 75

#ADDLER #FabricatingTheWorld #AussieManufacturing

Great post on the Sydney Harbour Bridge fabrication process! It’s amazing to think about the amount of planning and engineering that went into constructing such an iconic landmark. I appreciated the detailed explanations of the various stages of fabrication, from cutting and drilling the steel to assembling the arch segments. One question I have is how long did the entire fabrication process take from start to finish? Additionally, I would love to learn more about the maintenance and upkeep of the bridge to ensure its longevity for years to come. Thanks for sharing this fascinating insight into the construction of the Sydney Harbour Bridge!